Allied BIM

Powering 800% productivity increase in prefab

Fresh out of architecture school, Brian Nickel began designing plumbing systems for mega homes in the resort town of Big Sky, Montana. He found that the processes for turning 3D models into 40,000-square foot mansions were fraught with inefficiencies, especially for the parts of homes that are prefabricated like plumbing and HVAC.

“The machine shop is disconnected from the designers, and the field is disconnected from the shop,” said Nickel, who is no longer in residential construction. Today, he is co-founder of Allied BIM, a software company focused on solving those points of disconnection.

From traditional, manual workflows to innovative, automated solutions

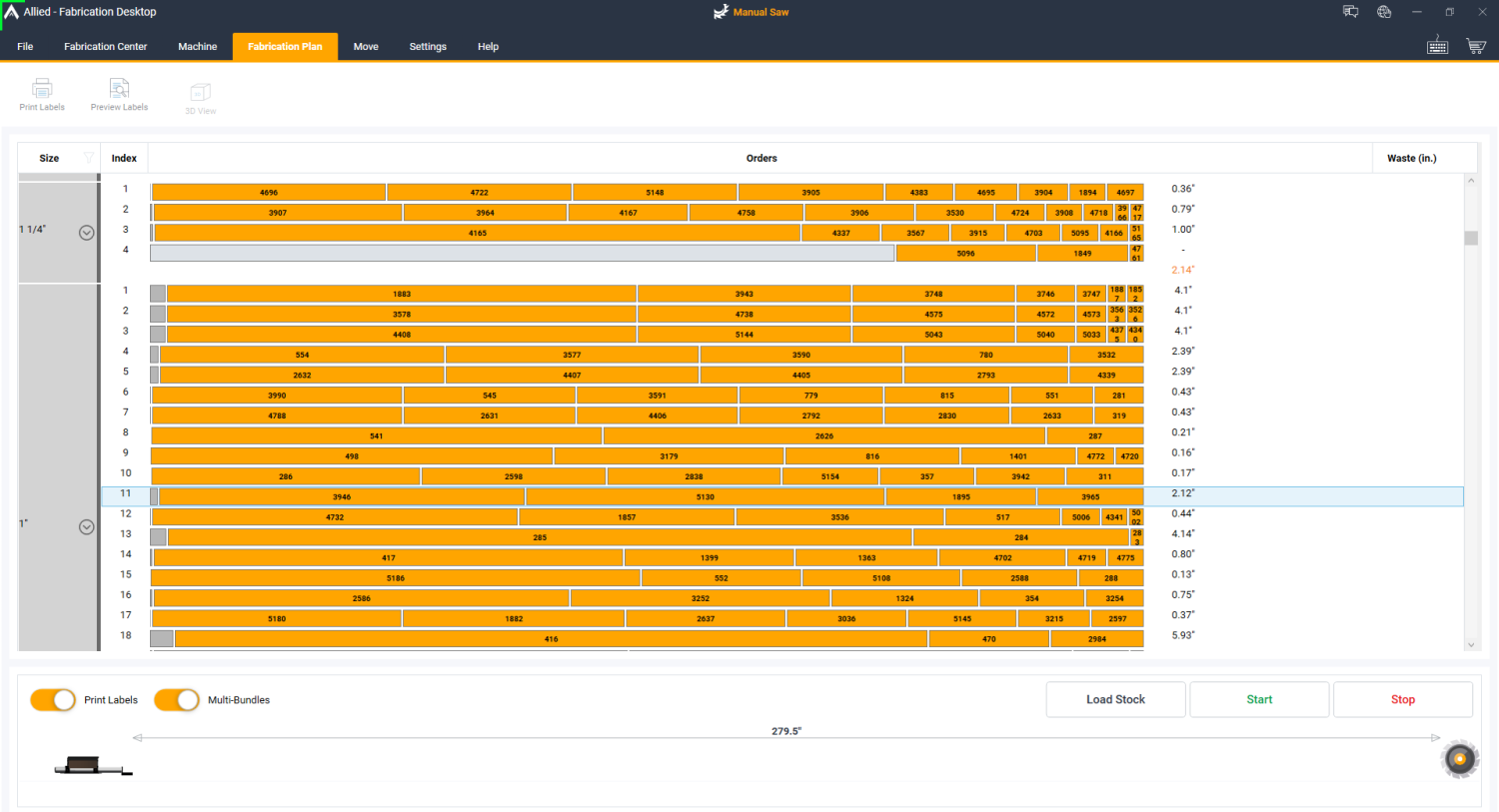

Traditionally, the shop receives a designer’s drawings on a thumb drive or sheets of paper. A worker manually types those instructions into a machine, which cuts the parts. A single error in that process can lead to expensive mistakes, such as ordering too many materials by as much as 40%.

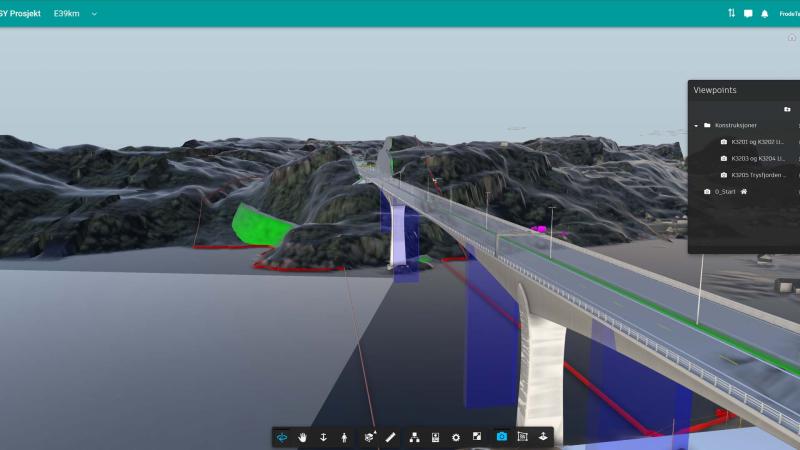

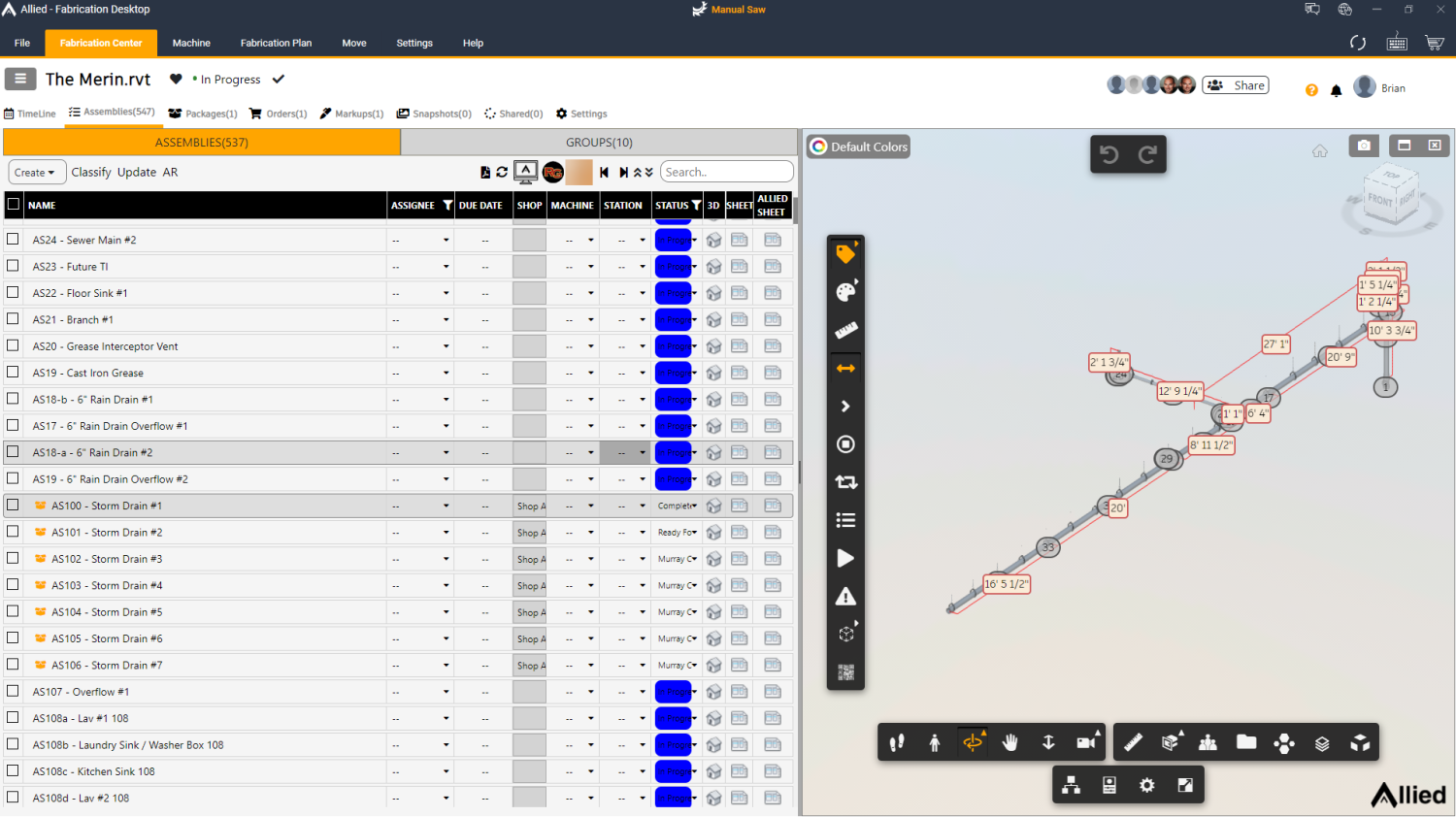

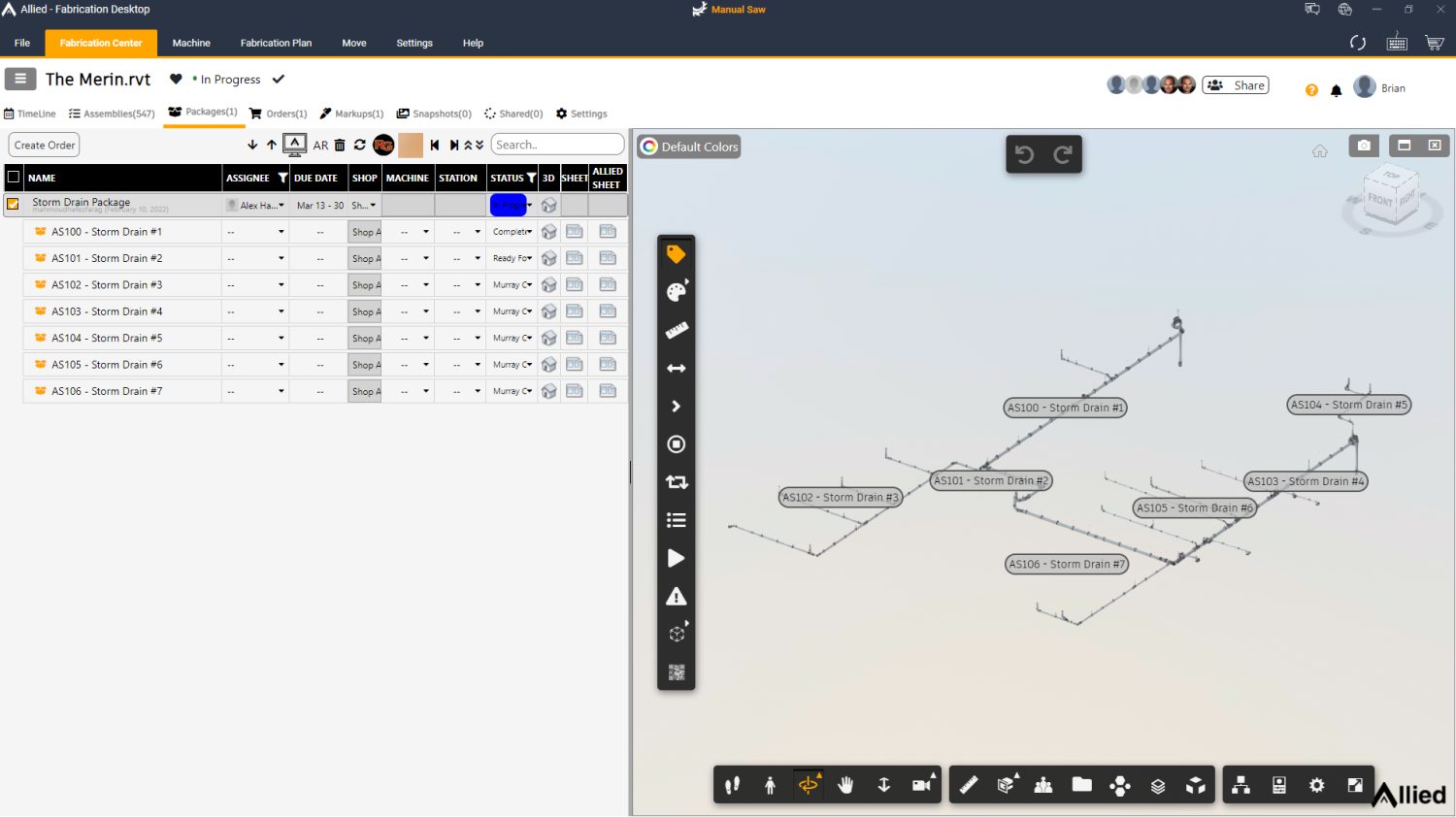

Nickel wondered if he could bridge the data gaps with software that connects digital drawings straight to the machine, eliminating the room for error and waste. His team found the solution in the cloud. Allied BIM created a plug-in that brings design data into a unified cloud platform, so it no longer lives in isolation on computers. Here, assembling instructions can flow directly to machines on the shop floor, giving every team member access to the latest information, right when they need it, no matter their location. Allied BIM built its solution with Autodesk Forge® APIs.

“Forge connects the unconnectable,” said Nickel. “When my business partner and I set out to solve this problem, the ‘aha moment’ was Forge.”

Using the traditional manual workflows, designers can send a machine shop about 10 drawings a day. But with Allied BIM’s automated data flow, they can now push through 80 spools—an 800% productivity gain. And because the data flows in both directions, the machine shop can also send designers real-time updates when they’re ready for more sets of instructions.

“Forge connects the unconnectable...when my business partner and I set out to solve this problem, the ‘aha moment’ was Forge.”

Closing the gaps between manufacturing and construction

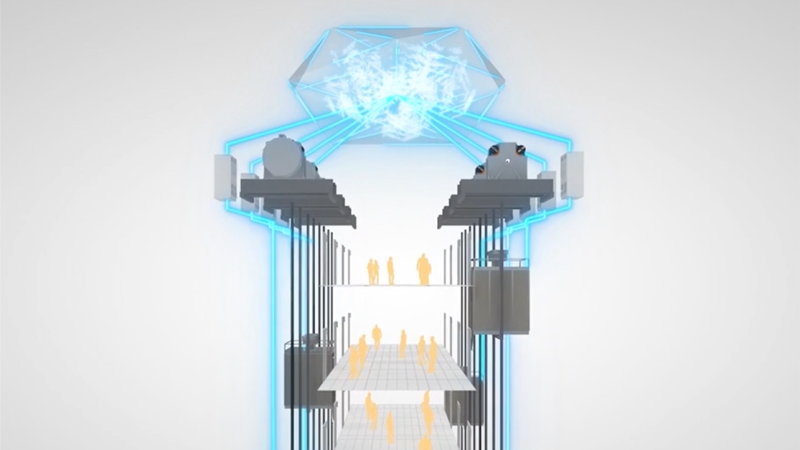

This type of digital transformation is fueling the industry’s evolution toward prefabrication and other offsite construction techniques. Improved data flows between manufacturing and construction processes help realize the advantages of offsite construction, including reducing waste and cost and improving sustainability. And the industry is seizing the opportunity. The offsite construction market is expected to reach $235 billion by 2030, an 80% increase in a decade.

Nickel at Allied BIM sees the potential, but he also sees the gaps that remain between manufacturing and construction workflows. That’s why Allied BIM is building a prefab ecosystem with Autodesk Construction Cloud and machine makers like RazorGage and Scotchman, with the goal of making data flow fluidly across the entire project lifecycle.

“It’s extremely important that the design process is connected with the people who are installing the work and everyone in between,” said Nickel. “We’re seeing engineers doing $150K systems that could be done for $40K. But to do better, we can’t be working in individual silos.”

“It’s extremely important that the design process is connected with the people who are installing the work and everyone in between,” said Nickel. “We’re seeing engineers doing $150K systems that could be done for $40K. But to do better, we can’t be working in individual silos.”

Maximizing performance in the machine shop

The benefits of Allied BIM’s model-to-machine software touch nearly every process in the machine shop, from improved labeling to more efficient assembly storage. These gains can only happen because the design data has been exposed in the cloud. For example, Allied BIM can apply an algorithm that dynamically nests linear cut lengths to maximize material use, reducing waste from 40% to 2%. Allied BIM is reimagining fabrication workflows today, but Nickel says they have their sights set on reshaping the entire industry. With data united on a cloud platform, Nickel envisions connecting shops around the globe—a network of machines that can flex and bend to market demands.

“If one shop is down and another doesn’t have work for a day, we have a machine ecosystem that can respond and maximize, a Door Dash for fabrication,” said Nickel. “We’re here to partner and create a movement.”

That’s next-level collaboration in an industry that’s remained disconnected far too long. But with a vision and platform technology that enables it, Allied BIM is laying the foundation for a new possible.

“If one shop is down and another doesn’t have work for a day, we have a machine ecosystem that can respond and maximize, a Door Dash for fabrication,” said Nickel. “We’re here to partner and create a movement.”